The difference between fulfillment center vs warehouse goes far beyond terminology. It directly impacts delivery speed, order accuracy, operating costs, and long-term growth. If logistics has become a bottleneck instead of a competitive advantage, this guide will help you understand when a fulfillment center makes sense, when a warehouse is enough and how to choose the right setup for your business.

What is a warehouse?

Warehouse definition

A warehouse is a logistics facility primarily designed for inventory storage. Its core function is to receive goods in bulk, store them efficiently, and release them when needed for distribution or further processing. Warehouses typically manage inventory at the pallet or case level and are optimized for space utilization and cost efficiency rather than speed.

Warehouses have long been a foundational component of supply chains across manufacturing, wholesale, and retail industries. Their role is to balance supply and demand by holding inventory until it is needed downstream.

Why warehouses matter in ecommerce

In ecommerce, warehouses still play an important supporting role. Many brands use warehouses to store bulk inventory before it is distributed to fulfillment centers, retail locations, or regional hubs. Warehouses are especially useful for long-term storage, seasonal stockpiling, or products with slower turnover.

However, when ecommerce brands rely solely on traditional warehouses to ship customer orders, they often face challenges related to speed, accuracy, and scalability. This limitation becomes more visible when comparing warehouse vs fulfillment center models.

What is a fulfillment center?

Fulfillment center definition

A fulfillment center is a specialized logistics facility built to process individual customer orders from start to finish. Once an order is placed online, the fulfillment center picks the ordered items, packs them securely, labels the shipment, and sends it directly to the end customer.

Fulfillment centers operate at the unit level rather than in bulk. Most are managed by third-party logistics (3PL) providers and are tightly integrated with ecommerce platforms through warehouse management systems (WMS) and order management systems (OMS).

Why fulfillment centers matter in ecommerce

For modern ecommerce brands, fulfillment centers are not just storage locations. They are customer-facing operations that directly affect delivery speed, order accuracy, and post-purchase experience. Fast shipping, real-time tracking, and easy returns are now baseline expectations.

In the comparison of fulfillment center vs warehouse, fulfillment centers are purpose-built to meet these ecommerce demands, making them a critical infrastructure choice for growing brands.

Fulfillment center vs warehouse: the similarities

Despite their differences, warehouses and fulfillment centers share some similarities. Both are usually large facilities capable of storing products for multiple businesses. Both handle inbound receiving, inventory organization, and outbound movement of goods.

These similarities often cause confusion, especially for businesses early in their ecommerce journey. The key differences become clear when examining purpose, operations, and customer orientation.

Fulfillment center vs warehouse: know the differences

Primary goal and operational focus

The primary goal of a warehouse is long-term inventory storage and cost efficiency. Warehouses are designed to hold goods until they are needed elsewhere in the supply chain.

A fulfillment center, by contrast, focuses on rapid, end-to-end processing of customer orders. Its goal is not just to store products, but to move them quickly and accurately from shelf to customer. This difference in purpose defines nearly every operational decision in the fulfillment center vs warehouse comparison.

Target customers and fulfillment orientation

Warehouses primarily serve businesses. Their customers are typically retailers, wholesalers, manufacturers, or distributors operating in B2B environments.

Fulfillment centers serve end consumers. They support direct-to-consumer (B2C) shipping, where delivery speed, packaging quality, and communication directly influence customer satisfaction. This B2C orientation explains why fulfillment centers invest heavily in technology and process optimization.

Day-to-day operational workflow

Warehouse operations are relatively static. Inventory moves in and out in large quantities, and daily activity often revolves around pallet handling, storage, and scheduled dispatches.

Fulfillment centers operate in constant motion. Orders arrive continuously throughout the day, requiring rapid picking, packing, and shipping of individual items. This dynamic workflow is essential for ecommerce brands that promise fast delivery.

Technology

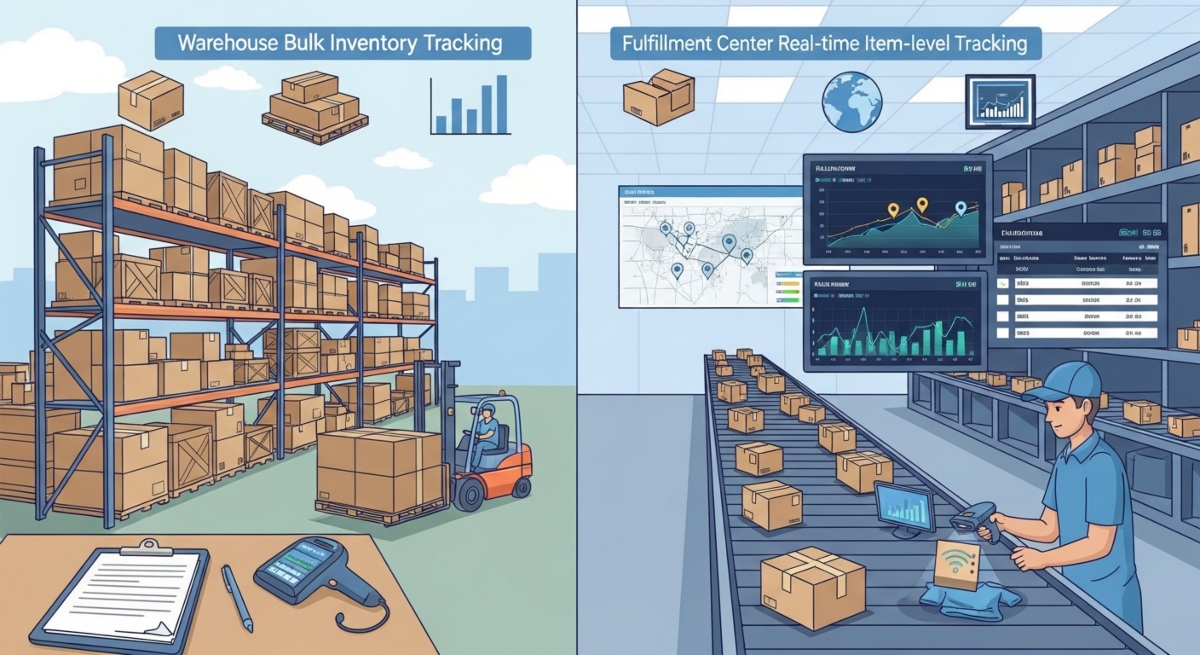

Technology is one of the most decisive differences in fulfillment center vs warehouse.

Fulfillment centers are powered by automation and system integration. Automated order fulfillment solutions reduce manual tasks and improve accuracy. Integrated OMS and WMS platforms synchronize orders, inventory, and shipping data in real time across multiple sales channels. Shipping automation connects directly with carriers to generate labels instantly and optimize routing. Real-time inventory management prevents overselling and stockouts.

Read more: Top 12 Best Order Fulfillment Software for Ecommerce Businesses in 2026

Warehouses typically rely on more basic inventory systems. These systems track pallet locations but often lack real-time, item-level visibility. Order preparation is more manual, integration with ecommerce platforms is limited, and responsiveness is lower.

For ecommerce brands that need agility, warehouses struggle to match the technological capabilities of fulfillment centers.

Costs and pricing structure

Cost structure differs significantly between the two models.

Fulfillment centers usually charge usage-based fees, including storage, picking, packing, and shipping. This pricing model scales with order volume, making it suitable for ecommerce businesses with fluctuating demand.

Warehouses typically charge based on space and time. Businesses pay for square footage or pallet positions regardless of how fast inventory moves. While this can be cost-effective for long-term storage, it becomes inefficient for high-velocity ecommerce operations.

Understanding this cost difference is essential when evaluating warehouse vs. fulfillment center options.

Read more: How to calculate fulfillment cost per order? Full guide & Formula

Customer experience

Customer experience is where the gap between the two models becomes most visible.

Fulfillment centers are designed to support fast delivery, accurate orders, and simple returns. Automated processes reduce errors, while branded packaging, tracking notifications, and streamlined returns enhance the overall customer journey.

Warehouses offer limited customer-facing services. Packaging is basic, customization options are minimal, and returns processing is slower. For ecommerce brands, these limitations can directly affect retention and lifetime value.

Inventory management

Inventory in a warehouse is managed in bulk and updated less frequently. This approach works well for storage but creates risks in ecommerce environments where stock availability must be accurate at all times.

Fulfillment centers track inventory in real time at the item level. Every pick, pack and ship action updates stock instantly, enabling accurate inventory visibility across channels and supporting better demand forecasting.

Facility location strategy

Warehouses are usually centralized to optimize regional or national supply chain efficiency. Their location prioritizes transportation cost savings over proximity to customers.

Fulfillment centers are often distributed closer to end customers. This placement reduces last-mile delivery time and shipping costs, supporting faster delivery promises.

Equipment and handling methods

Warehouses rely on heavy equipment such as forklifts, pallet jacks, and freight docks designed for bulk handling.

Fulfillment centers use handheld scanners, packing stations, labeling machines, and conveyor systems optimized for individual parcels. This difference reflects their distinct operational priorities.

Simplicity vs scalability in logistics design

Warehouses are well-suited for simpler, stable supply chains with predictable inventory flows. Fulfillment centers are designed for scalability, absorbing order spikes during peak seasons without disrupting service.

Many modern ecommerce brands use both models together, combining warehouse storage with fulfillment center execution.

Fulfillment center vs warehouse comparison table

| Feature | Warehouse | Fulfillment center |

|---|---|---|

| Primary goal | Long-term storage and cost efficiency | Rapid processing of customer orders |

| Customer type | Businesses (B2B) | End consumers (B2C) |

| Operations | Static, bulk-focused | Dynamic, item-level |

| Services | Storage, basic shipping | Picking, packing, shipping, returns |

| Technology | Basic inventory systems | Advanced WMS, automation |

| Location | Centralized | Close to customers |

| Equipment | Forklifts, pallets | Scanners, packing stations |

When should a brand choose a fulfillment center over a traditional warehouse?

Brands should choose a fulfillment center when they need more than storage. Fulfillment centers are ideal for ecommerce brands that require fast order turnaround, scalable operations, integrated services like kitting and returns, and a customer-focused logistics experience.

Outsourcing to a fulfillment center allows brands to reduce operational overhead and focus on growth rather than warehouse management.

Fulfillment center vs warehouse FAQs

Can a fulfillment center and warehouse be the same facility?

Yes. Some facilities operate as hybrid models, combining storage and fulfillment. However, one function usually dominates operational design.

Can you use both fulfillment center and warehouse together?

Many brands do. Warehouses store bulk inventory upstream, while fulfillment centers handle customer orders downstream, combining scale with speed.

Should my ecommerce brand use a fulfillment center or a warehouse?

If your brand ships directly to customers and relies on fast, accurate delivery, a fulfillment center is the better choice. Warehouses are better suited for bulk storage or internal fulfillment with less urgency.

How about fulfillment center vs distribution center?

A fulfillment center ships individual orders to customers, while a distribution center redistributes inventory in bulk to other facilities or stores.

How about warehouse vs distribution center?

Warehouses focus on storage, while distribution centers emphasize redistribution and throughput. Neither is optimized for customer-level fulfillment.

Amazon warehouse vs fulfillment center

The comparison of Amazon warehouse vs fulfillment center often causes confusion. Amazon fulfillment centers combine storage and fulfillment but are optimized for Amazon’s ecosystem. Traditional warehouses lack this level of automation and customer delivery integration.

Conclusion

Understanding the difference between fulfillment center vs warehouse is critical for ecommerce brands building a scalable logistics strategy. Warehouses provide cost-effective storage and support bulk inventory needs, while fulfillment centers deliver speed, accuracy, and customer-centric fulfillment.

Choosing the right model or combining both depends on business goals, sales channels, and growth stage. By aligning logistics infrastructure with customer expectations, brands can reduce costs, improve delivery performance, and scale sustainably.