Poor fulfillment leads to delays, stockouts and negative reviews, while an optimized process improves margins and brand trust. This guide breaks down the fundamentals, workflow, challenges and optimization strategies so ecommerce brands can strengthen their fulfillment performance at scale.

What is order fulfillment?

Order Fulfillment Definition

Order fulfillment is the end-to-end process of receiving inventory, storing products, processing customer orders, picking and packing items, and delivering them to the buyer. In ecommerce, order fulfillment covers every operational step that ensures the right product reaches the right customer at the right time. A strong fulfillment process supports accurate stock levels, smooth warehouse operations, and reliable shipping performance.

What is an example of order fulfillment?

A common example of order fulfillment is a customer placing an order on an online store. The order is transmitted to the fulfillment center, where staff pick the correct SKU, pack it using the appropriate materials, print a shipping label, and hand the package to a carrier such as UPS or FedEx.

The customer then receives tracking updates until the order arrives at their door. This simple flow illustrates how inventory, warehouse operations, and logistics work together in a complete fulfillment process.

Why does order fulfillment matter?

Fulfillment Ensures Operational Stability

A well-managed fulfillment system keeps the ecommerce engine running smoothly. High fulfillment accuracy helps maintain healthy inventory levels, optimize labor allocation, and deliver consistent shipping performance. When fulfillment slows down, errors increase and the overall customer experience is directly impacted.

Fulfillment Enables Scalable Growth

Efficient fulfillment allows brands to grow without compromising service quality. Faster pick-and-pack workflows, optimized storage layouts, and accurate inventory tracking make it easier to handle higher order volumes. By reducing errors and minimizing waste, strong fulfillment operations directly improve profitability.

Fulfillment Builds Customer Trust and Experience

Customers expect fast, transparent, and reliable delivery. They rely on accurate tracking updates and timely shipping. Late or incorrect deliveries damage trust, while seamless fulfillment strengthens brand credibility. Understanding what is order fulfillment helps ecommerce teams align operations with evolving customer expectations.

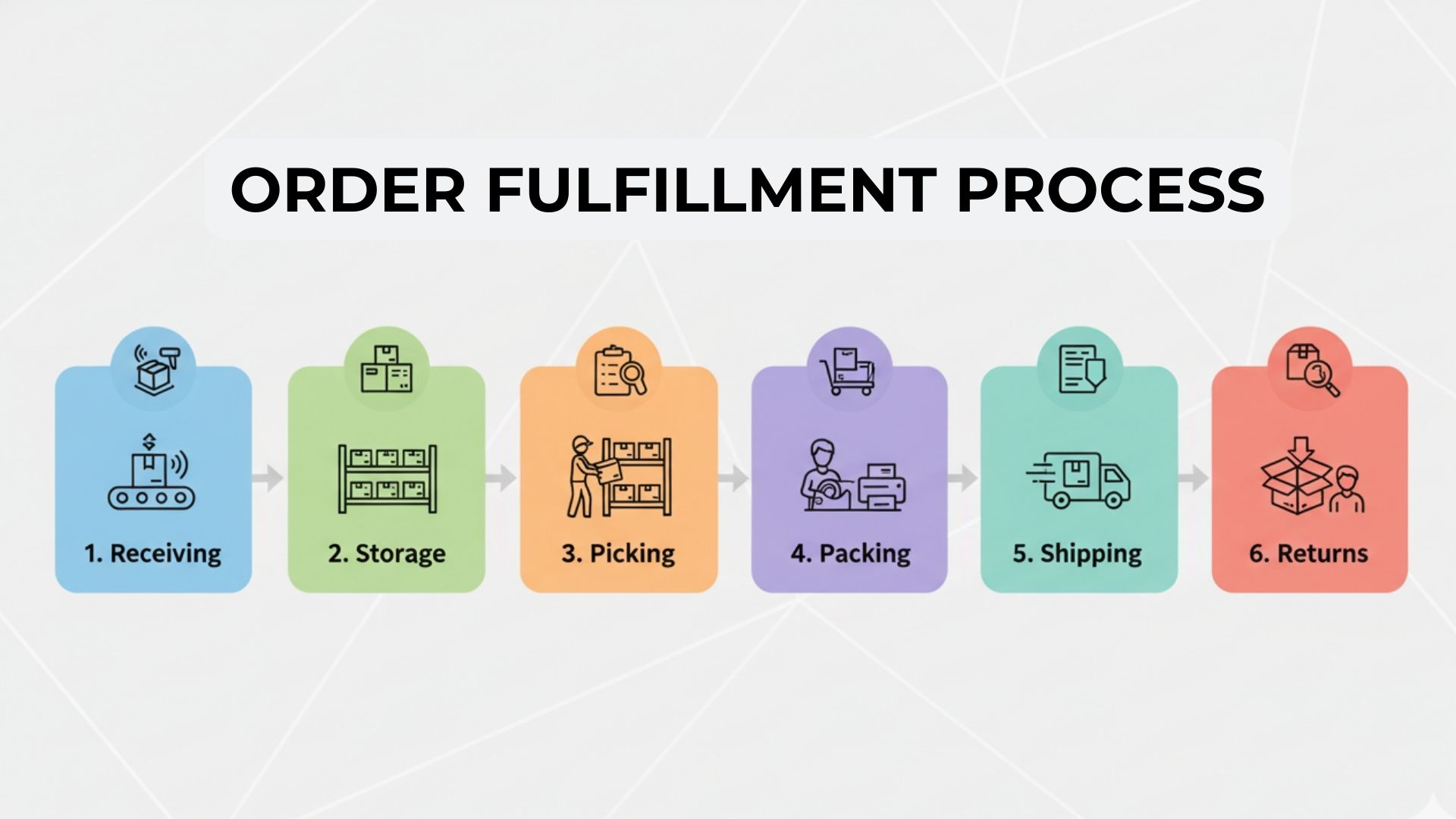

How the order fulfillment process works (step-by-step)

The order fulfillment workflow is a structured sequence of warehouse and shipping activities. Each stage contributes to the accuracy and speed of the overall process.

Receiving and quality check

The journey begins when inventory arrives at the warehouse. Staff inspect shipments, verify SKU quantities and check product conditions. Items are labeled and entered into the warehouse management system. Lack of accuracy at this stage creates discrepancies that affect picking and restocking later.

Inventory storage and organization

Products are placed into assigned storage bins, shelves or pallet racks. Efficient storage layout improves picking routes and reduces warehouse labor. High-demand SKUs are typically positioned closer to packing stations for quicker turnaround.

Order processing and picking

When an order is placed on the ecommerce store, the fulfillment system generates a pick list. Workers or automated robots retrieve the required items using barcode scanning to ensure accuracy. Mis-picks are a leading cause of customer dissatisfaction, making this step critical.

Packing and preparation

Items arrive at packing stations equipped with boxes, poly mailers, protective fillers and label printers. Staff select suitable packaging, verify the contents and attach the shipping label. Packaging quality impacts both customer perception and product safety during transit.

When customers track their package throughout the fulfillment journey, they may see different status labels at each stage. To understand what those updates mean and how they reflect progress in processing, visit our guide on what fulfillment status means.

Shipping and last-mile delivery

The packed order moves to the outbound dock, where it is sorted by carrier. Shipments are then picked up by UPS, FedEx, DHL, USPS or regional carriers. Tracking information syncs automatically with the ecommerce platform to notify customers.

Returns processing

Returns are an essential part of understanding what is order fulfillment. When items come back, the warehouse checks their condition, updates stock numbers and restocks eligible products. Efficient returns flow reduces inventory inaccuracies and improves customer experience.

Common challenges in the fulfillment process

Even well-established ecommerce stores encounter bottlenecks. Common issues include inaccurate inventory counts, slow picking times, shipping delays during peak seasons and high return rates. System integration failures between ecommerce platforms and fulfillment software also cause inconsistent order updates. Identifying these pain points is the first step toward improving efficiency.

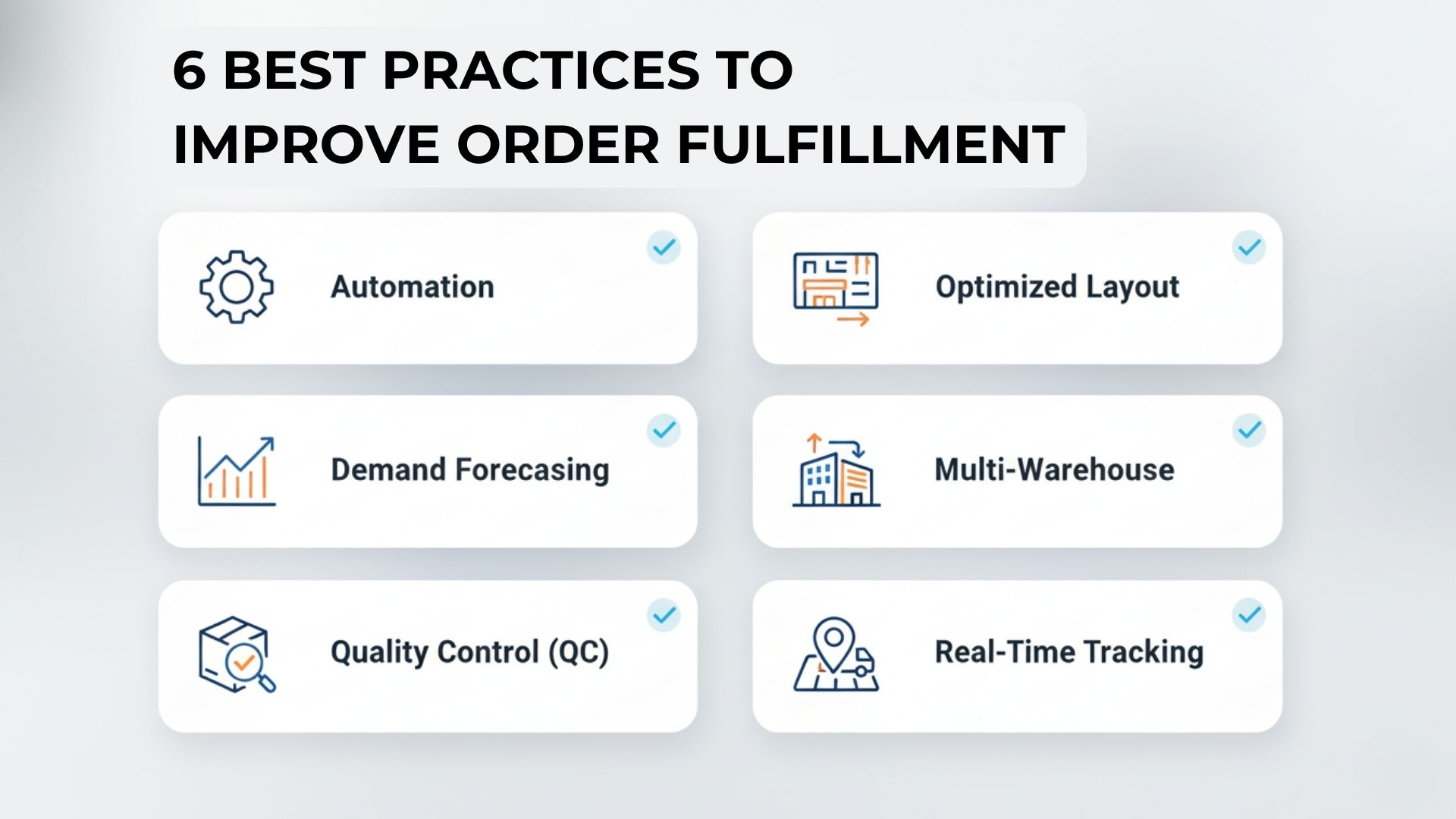

6 best practices to improve order fulfillment

Optimize your warehouse layout

A well-designed storage system minimizes walking distance for pickers and improves order throughput.

Invest in inventory forecasting

Forecasting tools reduce overstocking, stockouts and unnecessary storage fees.

Automate repetitive tasks

Barcode scanning, automated sorting and inventory syncing cut processing time and reduce human error.

Improve picking accuracy

Use batch picking, zone picking or wave picking depending on order volume and SKU variety.

Use real-time order tracking

Providing customers with accurate tracking reduces support inquiries and increases trust.

Expand to multi-warehouse or distributed fulfillment

Storing inventory in multiple regions shortens delivery time and reduces shipping costs.

Strengthen quality control

Consistent QC checks improve accuracy and reduce return-related costs.

Understanding what is order fulfillment allows businesses to choose optimization methods that fit their scale, order volume and product characteristics.

4 common order fulfillment models: Which one fits your brand?

Different fulfillment approaches support different growth stages and business models.

In-house fulfillment

Businesses manage storage, packing and shipping on their own. Best for small order volumes or custom products.

Third-party logistics (3PL)

A 3PL handles warehousing, picking, packing and shipping. Ideal for growing brands needing scalability and faster deliveries.

Read more: What is 3PL? Definition, how it works and key benefits

Dropshipping

Suppliers ship directly to customers. Best for beginners or businesses without capital to hold inventory.

Hybrid fulfillment

Combines in-house and outsourced fulfillment to balance speed, control and scalability.

Choosing a model depends on order volume, geographic distribution and the level of control a business wants over operations.

Essential technology in modern fulfillment

Technology determines how efficiently an ecommerce business can scale. Core systems include:

- Warehouse Management Systems (WMS)

- Order Management Systems (OMS)

- Inventory tracking tools

- Barcode and RFID systems

- Automated picking solutions

- Real-time carrier integrations

A modern fulfillment tech stack ensures accuracy, reduces labor costs and provides the visibility required for operational planning.

Conclusion

Understanding what is order fulfillment provides ecommerce brands with the clarity needed to build efficient, scalable and cost-effective operations. From receiving inventory to delivering the final package, each step of the fulfillment process affects both customer satisfaction and overall business profitability.

By optimizing warehousing, improving picking accuracy, leveraging automation and selecting the right fulfillment model, businesses can reduce operational friction and maintain competitive delivery performance. Whether you manage fulfillment in-house or partner with a 3PL, mastering this core function is essential for sustainable ecommerce growth.