As eCommerce expands, many businesses struggle with logistics complexity and rising fulfillment costs. Let BettaMax help you explore what is 3PL and how it helps companies streamline operations and improve customer experience.

What is 3PL and why it matters?

Understanding what is 3PL helps businesses evaluate its impact on cost efficiency, delivery performance and long-term scalability. Third-party logistics or 3PL, refers to ouinventory tsourcing logistics operations such as warehousing, transportation, control and order fulfillment to a specialized provider.

Many businesses search for terms like 3PL logistics meaning, what does 3PL stand for in logistics or what is 3PL work because the model directly affects cost efficiency, delivery performance and scalability.

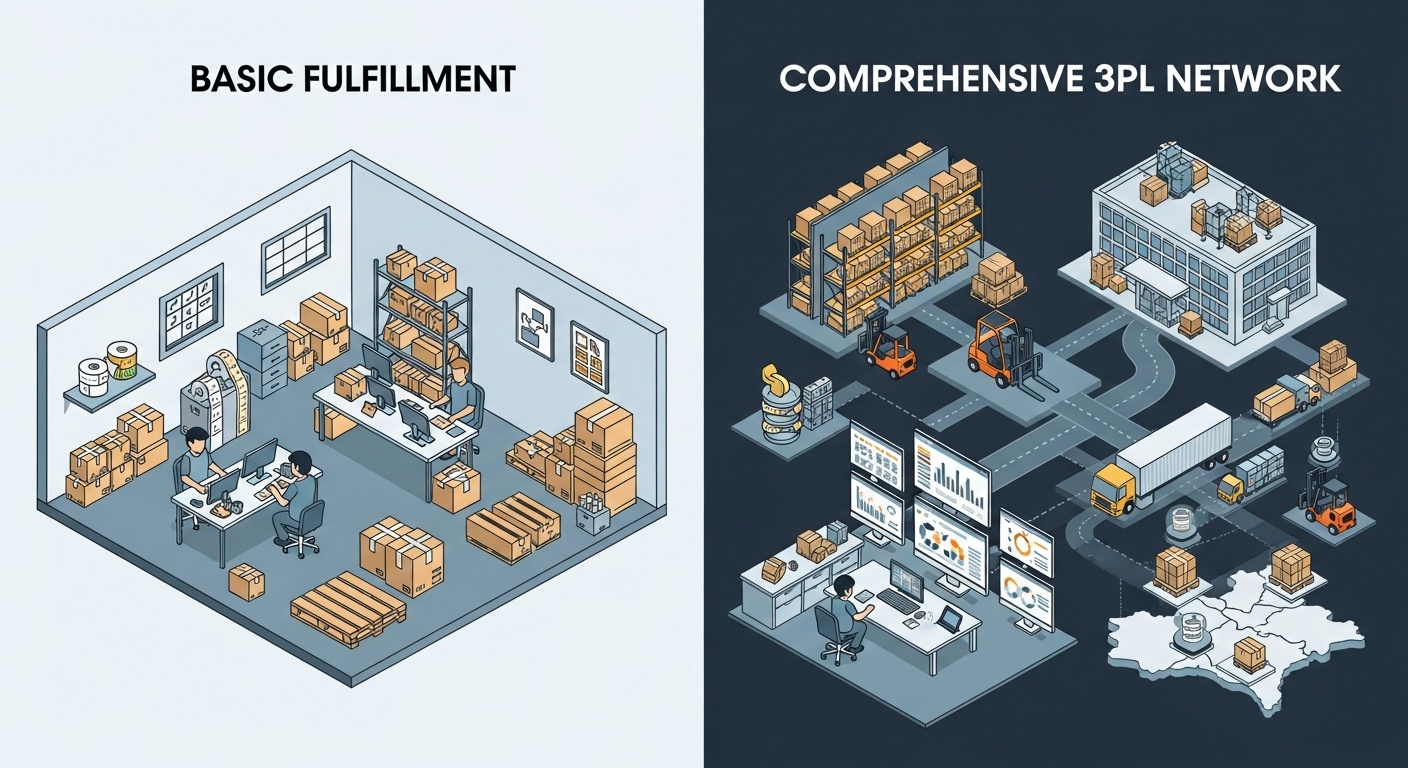

A 3PL goes beyond basic fulfillment centers by offering broader infrastructure. Fulfillment focuses on picking, packing and shipping orders, while 3PL covers a wider scope that includes freight coordination, inbound inventory handling, network optimization, returns management and value-added services.

The difference between 3PL and Fulfillment

Fulfillment is on segment of logistics. A 3PL provides the full structure around it.

To better understand how warehouse workflows are reflected in order tracking, you can explore our full guide on what does fulfillment status mean.

| Aspect | Fulfillment | 3PL Logistics |

| Primary role | Pick, pack and ship | End-to-end logistics management |

| Scope | Order-level tasks | Transportation, warehousing, inventory, freight |

| Technology | Order Management System (OMS) and shipping tools | OMS, WMS, freight systems and analytics |

| Strategic value | Supports eCommerce | Supports the entire supply chain |

Scope of 3PL services

A standard 3PL handles warehousing, order preparation, freight management, inventory control, reverse logistics and omnichannel integrations. Additional functions often include cross-docking, packaging customization, kitting and retail compliance.

Core benefits at a glance

Businesses rely on 3PLs to reduce logistics costs, increase delivery speed, improve inventory visibility and expand market reach without building new infrastructure. The model enables fast scaling during peak seasons while maintaining operational consistency.

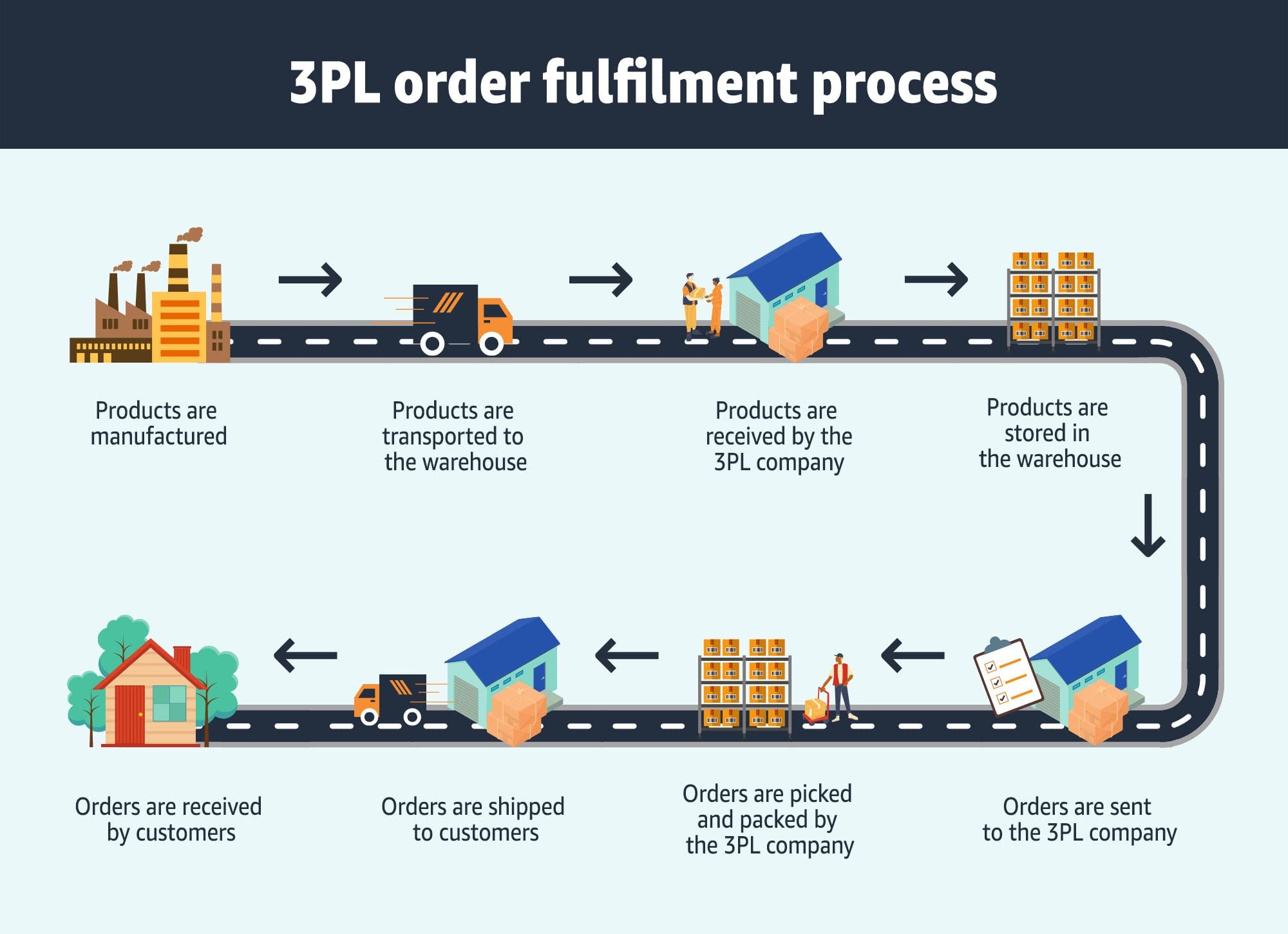

How does 3PL work?

Many companies want to understand what is a 3PL and how does it work before deciding to outsource. The process typically follows a structured fulfillment cycle supported by technology and warehouse systems.

Inbound: Products Manufactured, transported and received

To fully understand what is 3PL, it’s essential to see how the entire fulfillment cycle works from inbound receiving to final delivery. The fulfillment process starts when products are manufactured and transported to the 3PL warehouse. Upon arrival, the 3PL team unloads, checks quality, verifies quantities and logs inventory into the system. This ensures all items are ready for organized storage and future order processing.

Storage and inventory organization

After receiving, products are placed into designated storage areas. The warehouse team arranges items on shelves or pallets based on SKU type and picking efficiency. Proper storage helps maintain accurate inventory levels and supports fast order handling.

If you’ve ever seen an early status such as awaiting fulfillment during this stage, our dedicated guide explains exactly: What does awaiting fulfillment mean? Definition, impacts and tips

Order Processing: Picking, packing and preparation

When an order is placed, details flow to the 3PL system. Staff pick the required SKUs, scan them for accuracy and pack the items using appropriate materials. Labels, documents and any branding elements are added during this stage to prepare the order for shipment.

Shipping and final delivery

Once packed, the order is handed over to a carrier and shipped to the customer. Tracking updates are sent automatically. The process concludes when the customer receives the package, completing the 3PL fulfillment cycle.

What is 3PL Services?

A deeper look at what is 3PL also requires understanding the services a logistics partner manages on behalf of a business.

To compare 3PL operations with dedicated fulfillment facilities, you can also read our full breakdown of what is a fulfillment center.

Warehouse management and storage

3PL providers optimize pallet storage, bin shelving, climate-controlled sections and putaway processes. Warehouse layout focuses on SKU accessibility and efficient retrieval.

Transportation and freight shipping (FTL and LTL)

Freight services cover inbound and outbound transportation. Full-truckload (FTL) and less-than-truckload (LTL) options allow businesses to move goods at the right cost and speed. Carrier selection and rate negotiation are typically handled by the 3PL.

Inventory management

Inventory levels are tracked in real time through cycle counts, demand forecasting and replenishment alerts. Multi-location visibility helps prevent stockouts or overstocking.

Specialized Services (Kitting, Same-Day Shipping, Reverse Logistics)

Kitting combines multiple SKUs into a single bundle. Same-day processing supports fast delivery promises. Reverse logistics manages returns, inspections and restocking.

Order Fulfillment and pick and pack Operations

Fulfillment accuracy depends on consistent picking rules, packaging guidelines and standardized processes. Many 3PLs offer branded packaging and additional value-added services.

Omnichannel Integration

Retail EDI compliance, wholesale routing and marketplace integrations allow unified management of inventory across multiple sales channels.

3PL vs Alternative Solutions

These comparisons make it easier to identify what is 3PL in relation to 4PL, dropshipping and freight brokers.

3PL vs 4PL: What is the Difference?

A 4PL manages the entire supply chain at a strategic level while a 3PL executes day-to-day logistics operations. A 4PL may coordinate multiple third-party providers on the client’s behalf.

3PL vs Dropshipping: Detailed Comparison

Dropshipping ships directly from suppliers to customers without the merchant holding inventory. A 3PL stores the merchant’s owned inventory and provides higher control, faster delivery and consistent service levels. Dropshipping prioritizes low upfront cost, while 3PL supports brand-building and stable quality.

3PL vs Freight Brokers: When to Use Each

Freight brokers match shippers with carriers. 3PLs manage freight along with warehousing, fulfillment and inventory. Businesses choose brokers for transportation-only needs and 3PL when requiring end-to-end logistics.

Asset-Based vs Non-Asset-Based 3PLs

| Type of 3PL | Description | Strengths |

| Asset-Based Carriers | Own trucks, warehouses and equipment | Predictable pricing and high operational control |

| Non-Asset-Based Providers | Use networks of partners | High flexibility and broad coverage |

| Asset-Light Carriers | Mix of owned and outsourced assets | Balanced cost efficiency and reliability |

Key benefits of using 3PL Fulfillment

Many companies research what are the benefits of companies using a 3PL to evaluate how outsourcing will impact their operations.

Streamlined Operations and Cost Savings

Outsourcing eliminates the need for companies to lease storage space, hire warehouse teams or invest in logistics software. Operating costs become more predictable and aligned with business volume.

Scalability and Flexibility

Seasonal peaks and rapid growth become manageable because the 3PL expands capacity, labor and warehouse resources based on demand.

Enhanced Supply Chain Visibility and Analytics

Real-time dashboards allow businesses to monitor orders, stock levels and performance metrics. Data insights support smarter forecasting and inventory planning.

Risk Mitigation and Industry Expertise

3PLs manage compliance requirements, shipping regulations, cross-border documentation and operational risks that internal teams may not handle efficiently.

Network Scale and Reach

Most modern 3PLs operate multiple warehouses across regions, which helps reduce transit times and shipping costs.

Responsive Capacity and Full Coverage

Resources can be quickly adjusted during unexpected demand spikes, maintaining on-time delivery rates.

Access to Advanced Technology

Automated WMS tools, barcoding systems, robotics, analytics platforms and API integrations elevate operational accuracy and efficiency.

When should you use 3PL services?

The ideal time to adopt 3PL support usually occurs when order volumes increase, internal logistics becomes too complex or expansion to new markets is planned. Brands handling 50 to 500 orders per day often find substantial value in outsourcing. Companies with multi-SKU catalogs, omnichannel operations or cross-border strategies also gain better operational clarity through a 3PL.

Nearshoring and international expansion benefit from multi-location warehouses that position inventory closer to customers.

How to Choose the right 3PL provider

Many businesses face delayed shipments, hidden fees and poor inventory accuracy when choosing the wrong 3PL. Clear criteria are essential to avoid disruptions and protect customer satisfaction.

Evaluate expertise and experience

Industry specialization plays a major role in selecting a reliable partner. Sectors such as: apparel, electronics, cosmetics, perishables or oversized goods require specific handling capabilities.

Warehouse locations and geographic coverage

More warehouse locations usually translate to faster delivery and lower shipping costs. A multi-node network is advantageous for United States and European markets.

Customer support and service quality

Strong communication, fast response times, transparent reporting and dedicated account management ensure smooth operations.

Security and Operational Continuity

CCTV systems, strict access controls, audit logs and disaster recovery protocols help protect inventory and maintain uninterrupted operations.

Cost Structure and pricing models

Clear pricing with detailed receiving, storage, picking and shipping fees helps businesses maintain healthy margins. Hidden fees should be avoided.

Performance and service metrics

Metrics such as order accuracy, on-time ship rate and inventory shrinkage indicate operational reliability.

Integration capabilities

Robust API connections, native integrations and compatibility with ERP, WMS and eCommerce platforms ensure seamless data synchronization.

3PL Fulfillment FAQs

What does 3PL mean exactly?

It is the outsourcing of logistics and fulfillment tasks to an external specialist.

What is a 3PL vs a 4PL?

A 4PL manages the entire supply chain network. A 3PL executes logistics operations.

What are the different types of 3PLs?

Asset-based, non-asset-based, asset-light and industry-specific 3PLs.

Do major companies use 3PLs?

Large global brands rely on 3PLs to scale efficiently and expand into new markets.

What is the difference between a 3PL and dropshipping?

Dropshipping ships directly from suppliers. A 3PL stores and ships inventory owned by the merchant.

Why are 3PL services expensive?

Costs reflect warehouse operations, labor, technology, transportation management and value-added services.

How much does 3PL fulfillment cost?

Pricing depends on receiving volume, storage space, pick and pack complexity and shipping zones.

At what profit margin does 3PL make sense?

Many brands find it effective when margins exceed 20 to 30 percent, depending on the product category.

Conclusion

Third-party logistics offers a strong foundation for growing eCommerce and retail businesses. By outsourcing storage, transportation and fulfillment to specialists, companies gain efficiency, scalability and a better customer experience.

To get started, evaluate your logistics challenges, compare 3PL capabilities, review pricing structures and initiate a trial onboarding phase. Additional resources such as logistics audits and supply chain consultants can help refine your selection. By fully understanding what is 3PL, companies can decide when outsourcing logistics will improve efficiency and customer satisfaction.